Sharpening, a fundamental skill for maintaining the edge of various tools, from knives to scissors, is explored in this comprehensive guide. It delves into techniques, materials, safety, and specialized sharpening needs for a wide array of tools. From the basics of whetstones to advanced methods for intricate blades, this resource equips readers with the knowledge to keep their tools sharp and functional.

This guide provides a thorough overview of sharpening, covering everything from basic techniques to specialized procedures for different tools. We’ll explore various blade types, sharpening methods, and safety precautions, ensuring you can sharpen your tools effectively and safely. Understanding the intricacies of blade geometry and sharpening angles is key to achieving optimal results. We’ll also delve into the historical context of sharpening and its impact on different cultures and societies.

Sharpening Techniques

Sharpening is a crucial skill for maintaining the performance and safety of various cutting tools. Proper sharpening ensures a sharp edge, minimizing the risk of injury and maximizing efficiency. This section explores different sharpening methods, tools, and techniques, focusing on the specifics for various blade types.Sharpening techniques are multifaceted, involving the precise manipulation of the blade’s edge to restore its keenness.

The efficacy of the chosen method depends largely on the type of blade and the desired outcome. From simple honing to complex whetstone procedures, a tailored approach is essential for optimal results.

Knife Sharpening Methods

Knife sharpening is a common task, with a range of methods available. Each technique offers a different level of precision and control. Different blade materials and intended use influence the optimal approach.

- Whetstones: Whetstones, ranging from coarse to fine grit, offer a versatile approach. They gradually remove metal to restore the edge. Different grits are suited for different stages of sharpening, starting with a coarse stone to remove damage and finishing with a fine stone to achieve a keen edge.

- Honing Steel: Honing steel is a simple and effective tool for maintaining an existing sharp edge. It realigns the blade’s bevel without removing significant material, perfect for touch-ups between sharpening sessions.

- Electric Sharpeners: Electric sharpeners offer a quick and relatively easy way to sharpen a variety of knives. However, they often lack the precision of hand sharpening methods and may not be suitable for high-quality knives or blades needing extreme precision.

Scissors Sharpening Techniques

Scissors require a specific sharpening approach due to their complex blade geometry. Maintaining their cutting efficiency depends on the correct procedure.

- Whetstones: Using a fine-grit whetstone is ideal for maintaining the sharpness of scissors. Carefully sharpening both blades simultaneously, following the same angle, ensures symmetry and even sharpness.

- Specialized Scissors Sharpeners: These tools are designed for the specific geometry of scissors blades. They offer a guided sharpening process, reducing the risk of damaging the blades or producing uneven sharpness.

Razor Sharpening Techniques

Razor blades require a meticulous approach, given their thin and delicate construction. Precise sharpening is essential to maintain their sharpness and safety.

- Whetstones: Using a fine-grit whetstone and adhering to a precise angle is crucial for razor sharpening. A series of light strokes on both sides of the blade is needed to maintain the sharpness and symmetry.

- Honing Steel: Honing steel can be used to maintain the edge of a razor, but its use should be limited to light touch-ups. Repeated use can dull the blade over time.

Whetstone Sharpening Technique

Whetstones are a cornerstone of sharpening. Correct technique is paramount for efficient and safe sharpening.

- Angle: The angle of the blade relative to the stone is critical. Different blade types require different angles, typically ranging from 15 to 25 degrees.

- Pressure: Apply consistent, controlled pressure while maintaining a smooth, even stroke. Excessive pressure can damage the blade or the stone. A light but firm touch is recommended.

- Strokes: Maintain a consistent stroke pattern, always moving in the same direction, avoiding back and forth motions. The direction of strokes is crucial to prevent the creation of a burr.

Sharpening a Chef’s Knife with Diamond Sharpening Steel

This procedure demonstrates a method for sharpening a chef’s knife using a diamond sharpening steel.

- Preparation: Ensure the work area is clean and well-lit. Position the diamond sharpening steel on a stable surface. Hold the knife firmly, ensuring a secure grip.

- Angle: Establish the correct angle for the knife, typically 20 degrees. Adjust the angle as needed. This is essential to maintain an even edge.

- Strokes: Begin by making smooth, even strokes along the entire length of the blade. Maintain consistent pressure and the correct angle throughout the process.

- Refinement: Repeat the process on the opposite side of the blade, maintaining the same angle and pressure. This ensures a symmetrical edge.

- Checking: Assess the sharpness by carefully dragging the blade across a piece of paper. If the paper cuts cleanly, the knife is sharp.

Sharpening Materials and Equipment

Choosing the right sharpening materials and equipment is crucial for maintaining the edge of your tools. Proper selection and maintenance directly impact the longevity and effectiveness of your blades. Understanding the different types of sharpening stones, honing steels, and electric sharpeners is key to achieving a consistently sharp edge.

Types of Sharpening Stones

Sharpening stones, often called whetstones, come in various materials, each with unique characteristics and applications. Understanding these differences allows for informed selection based on specific needs and budget.

- Natural Stones: These stones, like Arkansas or India stones, are often composed of minerals like sandstone or quartzite. They offer a gradual, controlled sharpening action and are known for their ability to create a fine edge. Natural stones are typically more affordable than other types but require more care and maintenance due to their porous nature.

- Ceramic Stones: Ceramic stones are engineered for their consistent hardness and uniform structure. This consistency results in a precise and repeatable sharpening action, making them ideal for achieving a very fine edge. They are often faster to use than natural stones and maintain their sharpness for longer.

- Diamond Stones: Diamond stones utilize microscopic diamond crystals embedded in a matrix. Their extreme hardness allows for rapid and aggressive sharpening, ideal for removing significant amounts of metal quickly. Diamond stones are generally more expensive than other types but are excellent for restoring severely damaged edges.

Maintaining Sharpening Tools

Proper maintenance of sharpening tools is essential for their longevity and effectiveness. Ignoring maintenance can quickly diminish the quality of the sharpening process.

- Regular Cleaning: Thoroughly cleaning sharpening stones after each use, removing metal particles and debris, ensures the consistent quality of sharpening. This prevents the accumulation of debris, which can negatively impact the stone’s performance over time.

- Proper Storage: Storing sharpening stones in a dry, dust-free environment prevents moisture buildup and protects them from scratches and damage. Use a protective cover or case to shield stones from accidental contact.

- Regular Honing: Honing tools, like honing steels, require regular sharpening to maintain their effectiveness. Follow the manufacturer’s instructions for sharpening these tools to maintain their optimal condition.

Types of Honing Steels

Honing steels are essential for maintaining the edge of blades after sharpening. They realign the microscopic bevels and ensure a consistently sharp edge. Various types exist, each with its own characteristics.

- High-Carbon Steel: These steels are known for their hardness and durability, making them excellent for maintaining the edge of high-carbon steel blades. The higher carbon content ensures greater resistance to wear and tear, promoting long-term effectiveness.

- Stainless Steel: These steels are often preferred for their resistance to rust and corrosion, making them suitable for sharpening blades made from stainless steel. They are less prone to damage from moisture and environmental factors, promoting longevity.

- Ceramic Honing Steels: These offer a smooth, consistent honing action, ideal for achieving a razor-sharp edge. Their smooth surface reduces the risk of damaging the blade’s edge during the honing process.

Comparison of Sharpening Equipment

This table compares the pros and cons of different sharpening equipment, aiding in informed decision-making.

| Tool Type | Pros | Cons |

|---|---|---|

| Whetstone | Allows for precise sharpening, often affordable, good for various blade types | Can be time-consuming, requires skill and practice |

| Honing Steel | Quick and easy maintenance, inexpensive, maintains sharpness | Not suitable for resharpening, only for maintaining sharpness |

| Electric Sharpener | Fast and convenient, user-friendly, less skill required | Can damage blades if misused, may not achieve the same precision as whetstones |

Sharpening Safety Precautions

Proper sharpening techniques are crucial for achieving a sharp edge on tools, but safety should always be paramount. Neglecting safety precautions can lead to serious injuries, and understanding the potential hazards is vital for a safe and productive sharpening experience. This section details essential safety precautions to mitigate risks and ensure a secure sharpening environment.Sharpening, while often perceived as a simple task, can be hazardous if not approached with the appropriate safety measures.

Accidents, ranging from minor cuts to more severe injuries, can occur due to carelessness or a lack of awareness of the potential risks. Following the safety guidelines Artikeld below is crucial for preventing accidents and maintaining a safe sharpening routine.

Importance of Safety Gear

Thorough safety precautions are essential when handling sharpening tools and materials. Protective gear, such as safety glasses, gloves, and a dust mask, should be worn consistently to safeguard against potential hazards. Safety glasses prevent flying debris from entering the eyes, gloves protect hands from cuts and abrasions, and dust masks prevent inhalation of harmful particles. By consistently using these protective measures, individuals can significantly reduce the risk of accidents during sharpening.

Safety Precautions for Using Sharpening Tools

A meticulous approach to safety is critical when employing sharpening tools. Maintaining a stable workspace, ensuring adequate lighting, and keeping the sharpening area free from obstructions are crucial steps in preventing accidents. Proper tool handling techniques, such as using appropriate grips and avoiding forceful movements, are essential. Furthermore, it is vital to store tools and materials securely to prevent accidental injuries.

Always follow the manufacturer’s instructions and safety guidelines for each specific sharpening tool.

Sharpening your workflow can be super helpful, especially when you’re dealing with lots of photos. Employing smart tags, like those found on Smart tags , can dramatically streamline the process. This, in turn, leads to more efficient sharpening techniques, ultimately saving you time and effort.

- Secure Workspace: Ensure the sharpening area is free of clutter and obstructions. A stable and well-lit workspace minimizes the risk of slips and falls, and accidental contact with other objects. This includes clear access to the sharpening tools and materials.

- Protective Gear: Always wear safety glasses, gloves, and a dust mask. Safety glasses safeguard eyes from flying debris, gloves prevent cuts and abrasions, and dust masks protect against inhaling harmful particles.

- Tool Handling: Grip sharpening tools firmly but not forcefully. Avoid jerky or sudden movements during sharpening. Follow the manufacturer’s instructions for proper tool handling.

- Proper Lighting: Adequate lighting is crucial for clearly seeing the sharpening process and identifying potential hazards. Ensure the sharpening area is well-lit to avoid accidents due to poor visibility.

- Storage Practices: Store sharpening tools and materials securely in designated locations. This prevents accidental injuries and ensures the tools are readily accessible when needed.

Potential Hazards of Improper Sharpening Techniques

Improper sharpening techniques can lead to a variety of hazards. These include the risk of cuts, abrasions, eye injuries, and even more severe injuries. Inadequate sharpening techniques can result in an unsafe tool, which in turn can lead to accidents when using the tool. It is imperative to master the proper techniques to prevent such issues.

First Aid Procedures for Cuts or Injuries

Knowing the appropriate first aid procedures for cuts or injuries is critical. Immediate first aid, including stopping the bleeding, cleaning the wound, and applying a bandage, is vital for minimizing complications. In the event of a more serious injury, seeking professional medical attention is crucial. Knowing how to respond promptly and correctly can significantly reduce the severity of injuries.

- Minor Cuts: Apply gentle pressure to stop bleeding. Clean the wound with antiseptic solution and cover it with a sterile bandage. Monitor for signs of infection.

- Severe Cuts: Apply direct pressure to the wound to stop bleeding. Elevate the injured area if possible. Seek immediate medical attention.

- Eye Injuries: Immediately flush the affected eye with cool water for at least 15 minutes. Do not attempt to remove any foreign objects. Seek immediate medical attention.

- Other Injuries: Follow standard first aid procedures for the specific injury. If unsure, seek professional medical advice.

Sharpening for Specific Tools

Proper sharpening techniques are crucial for maintaining the performance and longevity of various tools. Different tools require tailored approaches, ensuring optimal cutting or shaping capabilities. This section delves into the specific sharpening needs of diverse tools, emphasizing the distinct requirements for each.

Woodworking Tools

Woodworking tools, such as chisels, planes, and saws, demand consistent sharpening to maintain precise cuts and efficient performance. The sharpening methods for these tools often involve honing on a sharpening steel or using a sharpening stone. The angle and pressure applied during sharpening directly impact the tool’s effectiveness. For example, a chisel requires a sharper angle for a clean cut than a plane.

Gardening Tools

Gardening tools, including shears, pruners, and hoes, require specific sharpening to maintain their cutting ability and prolong their lifespan. The sharpening methods for these tools often involve using a honing steel or a sharpening stone to restore the cutting edge. The type of metal used in the tool and the desired sharpness will dictate the appropriate sharpening method.

Scissors

Scissors, whether for fabric or other materials, demand specific sharpening techniques. Different types of scissors, such as fabric shears, utility scissors, and paper trimmers, require varying approaches. Fabric shears typically need a finer edge and more frequent sharpening compared to paper trimmers. Sharpness is paramount for precise cuts and to prevent damage to the material.

Sharpening Methods for Different Types of Scissors

- Fabric shears usually benefit from a fine-grit sharpening stone for maintaining a sharp edge. The goal is a smooth and consistent cutting edge to prevent fabric tearing.

- Utility scissors, often used for various tasks, require a more robust sharpening method. A coarse-grit sharpening stone may be necessary to restore the cutting edge. The key is to maintain the scissors’ overall shape for optimal use.

- Paper trimmers, designed for paper cutting, benefit from a combination of sharpening techniques. A honing steel or a fine-grit sharpening stone may be used to ensure a clean cut and prevent paper shredding. Proper sharpening allows for smooth and controlled cutting.

Comparison of Sharpening Procedures for Knives

| Knife Type | Sharpening Method |

|---|---|

| Chef’s Knife | A combination of sharpening stones (e.g., coarse and fine grit) is generally used to maintain a sharp, durable edge. A honing steel can be used to maintain sharpness between sharpening sessions. |

| Paring Knife | Fine-grit sharpening stones or honing steel are ideal for maintaining the precision edge of paring knives. These knives are often used for delicate tasks and require a sharp, yet precise edge. |

| Pocket Knife | Pocket knives often benefit from using a sharpening steel, followed by a honing steel to restore a sharp edge. The sharpening angle should be carefully considered to ensure safety and effectiveness. A sharpening stone can be used for more extensive sharpening. |

Sharpening Maintenance

Proper maintenance of sharpening tools is crucial for their longevity and effectiveness. Neglecting upkeep can lead to premature wear, reduced performance, and even safety hazards. This section Artikels the essential steps for maintaining your sharpening tools, ensuring peak performance and a long service life.Regular cleaning and proper storage are fundamental to the continued efficacy of sharpening tools. This ensures that they remain in top condition, preventing premature wear and tear and maintaining consistent performance over time.

Addressing signs of wear and tear promptly also ensures the safety of the user and the integrity of the tool being sharpened.

Cleaning and Storage Methods, Sharpening

Proper cleaning and storage prevent the build-up of contaminants and maintain the integrity of the sharpening tools. This extends the lifespan and ensures optimal performance.

- Cleaning Whetstones: Whetstones, whether natural or synthetic, require specific cleaning methods to maintain their effectiveness. Use a soft brush or cloth to remove any embedded debris. Avoid harsh chemicals or abrasive cleaners. For natural stones, a gentle water wash is often sufficient. Synthetic stones may tolerate a mild soap solution.

Thoroughly rinse and dry the stone after cleaning.

- Storing Sharpening Tools: Store sharpening tools in a cool, dry place to prevent moisture damage and rust. Use protective covers or cases to shield them from dust and other contaminants. Avoid storing them near sources of heat or extreme humidity. This protects the tools from moisture damage, which can cause rust and degradation. Keeping them covered prevents dust accumulation, further preserving their quality.

Signs of Tool Replacement

Recognizing when a sharpening tool needs replacement is essential for optimal performance and safety. Ignoring these signs can lead to poor results and even potential injuries.

- Whetstone Degradation: Significant pitting, cracking, or excessive wear on the whetstone surface indicate that it’s no longer effective. The loss of sharpness and consistency in the stone’s surface texture are clear indicators. If the stone’s surface is significantly altered, it’s time for a replacement. Consider the example of a chef’s knife, whose edge would no longer be effectively sharpened if the whetstone were severely worn.

- Poor Sharpening Performance: If the sharpening tool consistently produces subpar results, it’s likely time for a replacement. A noticeable decrease in the sharpness or quality of the sharpened edge is a strong indicator of tool degradation. This could result in a lack of sharpness or a dull edge.

Whetstone Cleaning Process

A meticulous cleaning process ensures a whetstone maintains its optimal sharpness and longevity.

- Gather Necessary Supplies: Gather a soft-bristled brush, a clean cloth, and water (or a mild soap solution for synthetic stones).

- Remove Debris: Gently brush away any loose debris or metal particles from the whetstone’s surface. This initial step is crucial in removing loose particles, preventing further damage to the whetstone’s surface.

- Rinse Thoroughly: Rinse the whetstone with clean water, ensuring all traces of debris are removed. Avoid using harsh chemicals or abrasive cleaners, which can damage the stone’s surface. This rinsing step removes any remaining particles or soap residue.

- Dry Completely: Dry the whetstone thoroughly with a clean cloth. Ensure all moisture is removed to prevent the growth of mold or mildew. Leaving moisture on the whetstone can lead to damage and deterioration.

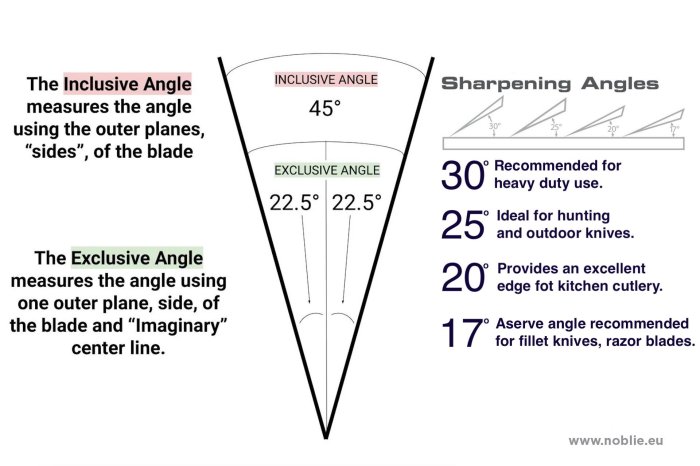

Sharpening Angles and Techniques

Proper sharpening angles are crucial for achieving a sharp edge that retains its sharpness for a longer period and for ensuring optimal performance of the tool. Incorrect angles can lead to a dull or uneven edge, reducing the tool’s efficiency and potentially compromising safety. Understanding the appropriate angle for different blade types is essential for achieving optimal results.Understanding the precise sharpening angle is vital for the effectiveness and longevity of the tool.

A correctly sharpened blade maintains its cutting ability and prevents premature dulling. This precision is achieved by considering the unique characteristics of each blade type, ensuring that the edge angle aligns with its intended function.

Determining the Correct Sharpening Angle

Accurately determining the sharpening angle is a crucial step in the sharpening process. Various methods exist for achieving this, ranging from using specialized sharpening guides to employing a simple trial-and-error approach. Careful observation and practice are essential for determining the correct angle. A consistent sharpening angle leads to a consistent and precise edge, ensuring optimal performance and durability.

Recommended Sharpening Angles

Consistent sharpening angles are essential for maintaining the quality and performance of tools. The table below provides a general guideline for recommended sharpening angles for different blade types. These angles are approximations and may vary slightly based on the specific tool design and intended use.

| Blade Type | Recommended Angle |

|---|---|

| Chef’s Knife | 15-20 degrees |

| Paring Knife | 20-25 degrees |

| Utility Knife | 20-25 degrees |

| Serrated Knife | 10-15 degrees per tooth |

| Scissors | 25-30 degrees per blade |

| Pocket Knife | 20-25 degrees |

| Surgical Scalpel | 15-20 degrees |

| Axe | 25-30 degrees |

Understanding Blade Geometry: Sharpening

Blade geometry significantly influences sharpness and performance. Different blade shapes and angles require specific sharpening techniques for optimal results. Understanding these intricacies allows for more effective and efficient sharpening, ultimately leading to a longer lifespan for your tools.The bevel and edge, fundamental components of blade geometry, directly impact sharpness. A precise understanding of their relationship is critical for successful sharpening.

Sharpening techniques must account for the specific geometry of the blade to maximize the cutting edge. Different geometries necessitate different approaches to achieve the desired level of sharpness and edge retention.

Different Blade Geometries and Their Impact on Sharpness

Various blade shapes exist, each influencing sharpness differently. The angle and curvature of the blade affect how well the material is able to hold an edge. The type of material from which the blade is made, its intended use, and the blade’s overall design all influence the ideal sharpening technique.

The Role of the Bevel and the Edge in Blade Sharpness

The bevel, the sloping surface leading to the cutting edge, is crucial for achieving sharpness. The bevel angle determines the blade’s ability to cut and hold an edge. The sharpness of the edge itself is directly correlated to the precision of the bevel’s angle and the smoothness of its surface. A well-defined bevel produces a sharp, consistent edge, while a poorly defined bevel leads to an uneven, less effective edge.

The edge itself is the very point of contact when cutting, and its sharpness and geometry directly impact the blade’s performance.

Relationship Between Blade Geometry and Sharpening Effectiveness

Blade geometry directly impacts the effectiveness of sharpening. A blade with a complex geometry may require a more involved sharpening process compared to a simpler one. Techniques must align with the blade’s design to avoid damage or compromising the intended performance. For example, a curved blade will necessitate a different sharpening approach than a straight blade. This approach needs to be adjusted for the material of the blade as well.

Examples of Different Blade Geometries and Corresponding Sharpening Techniques

| Blade Geometry | Description | Sharpening Technique |

|---|---|---|

| Straight Edge | A simple, linear blade. | A simple sharpening method, like honing, is effective. |

| Curved Edge | A blade with a curved or tapered edge. | Requires a method that accounts for the curvature, such as a guided sharpening stone or strop. |

| Serrated Edge | A blade with a series of small teeth. | Needs a specific approach that focuses on sharpening the individual teeth, such as a file or fine grit sharpening stone. |

| Knife | A common example with a variety of geometries. | Sharpening techniques for knives often involve honing, stropping, and the use of sharpening steels. |

Troubleshooting Sharpening Issues

Troubleshooting sharpening issues is crucial for maintaining the optimal performance of your tools. Identifying the root cause of a dull blade or other sharpening problems allows for targeted solutions and prevents further damage. Understanding the common problems and their solutions ensures that your sharpening efforts yield the best possible results.A systematic approach to troubleshooting sharpening problems is essential.

By identifying the source of the issue, you can select the appropriate corrective measures and avoid making mistakes that could further compromise your tools. This process involves examining the blade’s geometry, the sharpening technique, and the materials used.

Common Sharpening Problems and Their Causes

Common sharpening problems often stem from errors in technique, material selection, or blade geometry. A dull blade, for example, could be due to insufficient sharpening angle, improper stroke direction, or the use of unsuitable sharpening materials.

Solutions for Addressing Sharpening Issues

Addressing sharpening problems requires a methodical approach. If a blade is dull, re-evaluate the sharpening angle and technique. Ensure consistent and controlled strokes, applying even pressure. Consider whether the sharpening material is appropriate for the blade type. If using abrasive stones, ensure the stones are properly lubricated and maintained.

Sharpening images often involves adjusting the contrast and details, but understanding the original image’s metadata, like EXIF data, EXIF data , can significantly impact the sharpening process. Knowing the original settings helps fine-tune sharpening parameters for optimal results and prevents oversharpening, ensuring a clean and crisp final image.

Troubleshooting Steps for Various Sharpening Problems

The following table Artikels troubleshooting steps for common sharpening problems.

| Problem | Cause | Solution |

|---|---|---|

| Dull Blade | Insufficient sharpening angle, improper stroke direction, unsuitable sharpening material, or inadequate sharpening pressure. | Verify the correct sharpening angle for the specific tool. Practice consistent, controlled strokes in the appropriate direction. Select a sharpening material suitable for the blade type. Ensure sufficient pressure is applied during the sharpening process. Consider re-evaluating your technique or seeking guidance from resources like videos or tutorials. |

| Blade Striations (Scratches) | Incorrect sharpening angle, insufficient lubrication, or the use of an abrasive sharpening material that is too coarse. | Ensure the sharpening angle is correct. Use a lubricant when sharpening, especially with abrasive stones. Select a finer-grit sharpening material to remove scratches. Adjust the sharpening technique, if necessary. |

| Blade Wobbling/Bent Blade | Excessive force during sharpening, improper support during sharpening, or incorrect sharpening angle. | Apply even pressure during sharpening, avoiding excessive force. Ensure the blade is properly supported during the sharpening process. Verify the correct sharpening angle for the specific tool. Consider consulting with a professional if the blade is severely damaged. |

| Uneven Sharpening | Inconsistent pressure during sharpening, improper sharpening technique, or a non-uniform sharpening surface. | Maintain consistent pressure throughout the sharpening process. Use a consistent sharpening technique, ensuring even strokes. Inspect the sharpening surface for any imperfections or irregularities. Consider using a sharpening steel or honing tool to refine the edge. |

Sharpening Practice and Improvement

Mastering sharpening techniques requires dedicated practice and a systematic approach. Consistent repetition, coupled with focused analysis of your work, will steadily elevate your sharpening skills. This involves understanding your tools, materials, and the specific needs of different blade types.Sharpening, like any craft, benefits greatly from a structured learning process. It’s not simply about repetition; it’s about learning from each sharpening session and adjusting your technique based on feedback.

Identifying areas for improvement and incorporating new strategies are crucial for continued growth.

Strategies for Sharpening Practice

Consistent practice is essential for sharpening proficiency. Begin with simpler tasks and gradually increase complexity. Start with practicing on scrap materials before moving to valuable tools. This method ensures minimal risk of damage while allowing you to refine your technique. Also, analyze your work meticulously.

Document your sharpening process, noting specific techniques used, blade types, and the results.

Tips for Sharpening Enthusiasts

Regular practice sessions, even short ones, are more effective than sporadic, long sessions. Focus on quality over quantity. Each sharpening session should be an opportunity to learn and refine your technique. Employ a variety of sharpening methods to expand your repertoire and discover the most effective approach for different tools.

Honing Sharpening Skills for Different Tools

Different tools demand tailored sharpening techniques. For example, honing a chef’s knife necessitates a different approach than sharpening a saw blade. Understanding the specific geometry of each tool and the desired sharpness level is crucial. Always consult resources dedicated to the particular tool type for optimal results.

Importance of Consistent Practice

Consistent practice is fundamental to sharpening skill improvement. Regular sharpening sessions will solidify your understanding of angles, techniques, and material interactions. Each sharpening session should be an opportunity to refine your technique, experiment with various angles, and analyze the results. A dedicated schedule, even if it’s just a few minutes each day, can significantly impact your sharpening abilities.

Over time, you will develop a deeper understanding of blade geometry and the subtle nuances of sharpening. This will enable you to produce consistently sharp blades with precision and efficiency.

Historical Context of Sharpening

Sharpening, a fundamental skill for millennia, has played a crucial role in human history. From the creation of the earliest tools to the refinement of modern instruments, the ability to maintain and enhance cutting edges has been essential for survival, progress, and cultural expression. This historical context reveals a fascinating interplay between technological advancement, societal needs, and the evolution of sharpening techniques.The development of sharpening techniques reflects the continuous interplay between human ingenuity and practical necessities.

As societies evolved, so did their tools, and consequently, the methods for maintaining their sharpness. This evolution is not merely a technological progression but also a reflection of cultural values and priorities.

Significance of Sharpening Techniques

Sharpening techniques have always been more than just a practical skill. They have held cultural significance, reflecting the societal values and priorities of different eras and civilizations. The ability to maintain sharp tools was often linked to survival, efficiency, and even prestige. Highly skilled artisans and craftsmen, for example, were renowned for their mastery of sharpening techniques, demonstrating their dedication and precision.

Evolution of Sharpening Tools

The progression of sharpening tools mirrors the advancement of human technology. Early humans likely used naturally occurring stones or rough materials to sharpen their tools. Over time, more sophisticated tools emerged, like whetstones, honing steels, and specialized sharpening devices. These advancements corresponded with growing complexity in tool designs and their associated tasks.

Examples of Historical Sharpening Methods

Early humans likely utilized naturally occurring stones for sharpening. Ancient civilizations employed various methods, including the use of abrasive materials like sand or minerals, and progressively developed more refined techniques. The Egyptians, for instance, used specialized stones for sharpening their tools and weapons. Furthermore, ancient civilizations in the Middle East and Asia utilized different materials and techniques, demonstrating a diversity in sharpening practices across cultures.

Historical accounts and archaeological findings provide valuable insight into the techniques employed.

Impact of Sharpening on Various Cultures and Societies

Sharpening’s impact on cultures and societies is multifaceted. It directly affected survival, enabling hunting, agriculture, and crafting. In warfare, the sharpness of weapons dictated battlefield outcomes. Furthermore, sharpening skills were often passed down through generations, fostering a deep understanding of craftsmanship and cultural heritage. For example, the development of high-quality steel and the associated sharpening techniques contributed to the economic strength of certain societies.

Advanced Sharpening Techniques

Mastering advanced sharpening techniques allows for the precise maintenance of specialized blades, crucial for optimal performance and longevity. Understanding the nuances of different blade types and employing specialized tools is key to achieving exceptional results. These techniques go beyond basic sharpening and target achieving the ideal edge geometry for specific tasks.

Sharpening Curved Blades

Curved blades, such as those found on knives with intricate designs or specialized tools, require careful attention to maintain their unique geometry. A crucial aspect of sharpening curved blades is the recognition of their individual contours. Applying consistent pressure and angle across the entire curve is essential to avoid uneven sharpness. This often necessitates using a variety of sharpening stones or honing steel to achieve the desired result.

Specialized Blades and Tools

Specific blade types demand tailored sharpening methods. For instance, serrated blades necessitate techniques that accommodate their unique tooth patterns. Similarly, blades with complex shapes, like those on carving knives or surgical scalpels, demand meticulous attention to maintain their sharp, precise cutting edge.

Examples of Specialized Sharpening Tools

A range of tools are employed in advanced sharpening, each designed for specific blade types. These tools include:

- Honing Steel: A honing steel, also known as a sharpening steel, is a versatile tool for maintaining the sharpness of a blade’s edge. Its use is often for refining and restoring the sharpness of an already sharpened blade. The consistent, controlled strokes along the blade edge help align the cutting edge for a sharp edge. A honing steel is not typically used for initial sharpening.

- Ceramic Sharpening Rods: Ceramic sharpening rods are known for their fine grit and consistent sharpness. Their hardness allows for precise sharpening on delicate blades without damaging the blade’s surface. These rods are particularly useful for blades with intricate curves and fine details.

- Diamond Sharpening Plates: Diamond sharpening plates offer a very high level of precision and are often used for extremely fine sharpening work, or in cases where an exceptional edge is required. The diamond particles offer superior abrasiveness and help create a remarkably sharp edge. They are typically used for specialized blades, such as surgical scalpels or razor blades.

Last Word

In conclusion, mastering sharpening involves understanding the intricacies of blade geometry, technique, and safety. This guide provides a robust framework for tackling various sharpening needs, from everyday kitchen knives to specialized woodworking tools. Remember, consistent practice and adherence to safety precautions are crucial for achieving optimal results and maintaining the longevity of your tools. Sharpening is more than just a skill; it’s a gateway to efficient tool use and a lasting connection with your craft.

Questions Often Asked

What are some common mistakes people make when sharpening?

Using improper angles, applying inconsistent pressure, and not maintaining sharpening tools can lead to dull blades and potential injuries.

What is the best type of whetstone for a chef’s knife?

A good quality ceramic or diamond whetstone is suitable for chef’s knives. The best choice depends on the specific knife and desired outcome.

How often should I sharpen my knives?

The frequency of sharpening depends on the type of knife and how often it’s used. Regular use will require more frequent sharpening.

What are the signs that a sharpening tool needs replacing?

Significant wear, loss of sharpness, or uneven surface texture indicate that a sharpening tool may need replacing. Consult the product specifications for details.